WASSENBURG FIBERSCOPE WASHER-DISINFECTOR ADAPTASCOPE WD440 SCOPE WASHER

WASSENBURG FIBERSCOPE WASHER-DISINFECTOR ADAPTASCOPE WD440 SCOPE WASHER

Fr4,830 (CHF)

or

Call + 41 (0)27 720 41 00

Description

Designed for controlled cleaning and disinfection of flexible endoscopes and other heat-sensitive medical devices. Our easy-to-use WASSENBURG® WD440 PT offers you the highest levels of control and safety thanks to an optimized workflow.

WASSENBURG® WD440 PT

Endoscope washer-disinfector

Optimum workflow safety

TOTAL SOLUTION

A clean and disinfected endoscope is an essential prerequisite for ensuring the safety of every patient procedure. That's why we offer a complete range of systems, consumables and services. endoscope reprocessing cycle: the total solution.

FOR EVERY PATIENT WITH A SAFE ENDOSCOPE

The WASSENBURG® WD440 PT is designed for the controlled cleaning and disinfection of flexible endoscopes and other heat-labile medical devices. Our user-friendly WASSENBURG® WD440 PT provides you with the highest levels of control and safety.

WASSENBURG® WD440 PT BENEFITS

■ ISO 15883 compliant

■ Optimum safety

■ Process assurance

■ user-friendly

■ high capacity

■ Workflow security

■ total traceability

ISO 15883 COMPLIANT

The WASSENBURG® WD440 PT is fully compliant with ISO 15883 and contains an IMS system that is completely independent of the process controller. It monitors critical process parameters, by present the process and activating data analysis of critical process parameters in Process Manager.

OPTIMUM SAFETY

To ensure complete cleaning and disinfection of endoscopes, the WASSENBURG® WD440 PT contains a single basin and a spiral tube system. Fluid flow in the spiral tube lifts the distal end of the wall, allowing fluid to contact it everywhere.

Wassenburg's proven single-channel connection and pumping technology is the core of the system. Each endoscope channel is individually reprocessed and controlled for connection, flow, pressure and blockage.

SAVE THE PROCESS WITH RFID

The WASSENBURG® WD440 PT is equipped with radio frequency identification (RFID) to guarantee safe, traceable handling of treatment chemicals and bacterial filters. Before starting a process, the WASSENBURG® WD440 PT checks that cans are in the correct position, past expiration dates and other critical parameters, thus minimizing the risk of human error.

CONVIVIAL

The user interface of the WASSENBURG® WD440 PT is designed around intuitive, touch-free functions.

surgery. Hands-free operation of the lid, using foot sensors, means ease of use and reduces the risk of cross-contamination. Clear LED bars on the machine's front panel indicate process status.

Color-coded connection facilitates easy, seamless endoscope connection, aided by an intuitive color Touch Screen that guides the user through all the necessary steps.

HIGH CAPACITY

Our EndoHigh® treatment chemicals - a detergent in combination with peracetic acid (PAA) Gold Glutaraldehyde (GTA) - are developed exclusively for Wassenburg washer-disinfectors.

All processes are tested in vitro and in accordance with ISO 15883. They deliver excellent, safe process performance and a rapid endoscope reprocessing cycle (22 minutes AAP).

Two separate operating basins provide easy access to individually loaded and connected endoscopes, avoiding unnecessary waiting. The tanks are specially designed to minimize water consumption and maintain a constant process temperature. In addition, contact between the endoscope and the tank is reduced to a minimum.

SAFETY IN THE WORKFLOW

The WASSENBURG® WD440 PT can be wall-mounted, providing physical separation between clean and contaminated areas, with very low air leakage. It controls the endoscope Central Sterilization Departments.

FULL TRACEABILITY

Our solutions are designed to provide flexible endoscope control and processing. Traceability is the key to guideline control and operation. Integrated traceability helps the user quality systems.

All stages of the WASSENBURG® WD440 PT are tracked and monitored in detail, with reporting to an integrated printer WASSENBURG® Process Manager software. Process data is collected and provides useful information on all processes that have occurred in the washer-disinfector.

Process Manager works seamlessly with the WASSENBURG® WD440 PT to comply with regulations, and provides valuable information on the day-to-day operation and availability of your endoscopes.

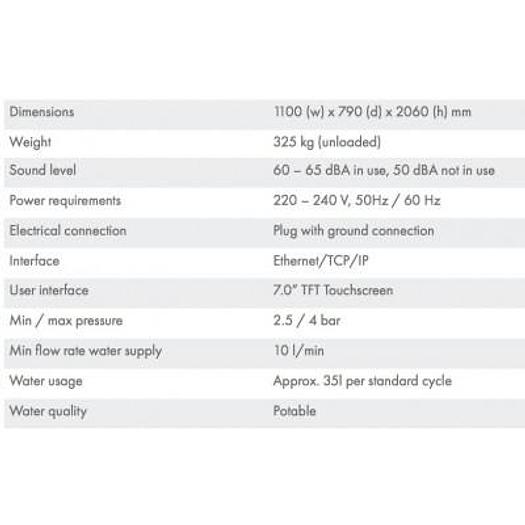

Specifications

| Condition | Used |

| Stock Number | 6540 |